| Erection & Commissioning |

|

Since incorporation in 2010, VJIKKS ENGG POWER (M) SDN BHD, Malaysia have

been growing steadily and with its New launching of VJIKKS ENGG POWER PTE LTD,

Singapore it shall continually grow further.

With the strong team of Indian and Malaysian Engineering professionals who are experienced

in Erection,Commissioning,Operation and Maintenance of Power, Chemical and Refinery Plants,

the company has started entering vigorously into

Design,Engineering,Manufacturing,Installation,Commissioning and also Training and Handing

over.

One such a typical example of a project which was recently completed by the company is the

State of the Art Chlorine Gas Distribution System for a State of the Art Bismuth Refinery

Plant set up by world renowned 5N PLUS,Canada in Laos.

5N Plus ,Canada is the leading producer of specialty metal and chemical products. 5N Plus

deploys a range of proprietary and proven technologies to produce products which are used in

a number of pharmaceutical, electronic and industrial applications.

The project handled by VJIKKS ENGG POWER (M) SDN BHD is just one of many examples of

projects handled by their team of Engineering Professionals.

Various projects executed can be seen in the various photographs exhibited here and in the

list of critical Erection Projects

|

| |

|

|

| |

|

|

| |

|

| |

|

DESIGN,ENGINEERING,SUPPLY,INSTALLATION,TESTING & COMMISSIONING OF IMPRESSED CURRENT CP FOR JETTY

IN KAPAR ENERGY VENTURE

15 Nos. of newly designed anodes to resolve the problem of frequent failure of old designed

anodes ; Installation included cabling, wire rope etc.

|

| |

|

| |

|

DESIGN, ENGINEERING, SUPPLY, INSTALLATION,TESTING,COMMISSIONING OF ELECTRICAL CIRCUIT FOR ECP CELL

VOLTAGE MONITORING IN PHALAWAN POWER PLANT FOR SANILEC ELECTROCHLORINATOR.

Voltage drop across electrode assemblies is a very good indicator of ageing or any defect of electrode.

Hence, a unique system was designed and installed to enable customer to record voltage drop without the

need to access the live bus bars, anodes and cathodes.

|

|

|

| |

|

DESIGN, ENGINEERING, IMPLEMENTATION OF MODIFICATION IN GAS TURBINE COMBUSTION CHAMBERS SOHAR POWER &

DESALINATION PLANT, OMAN.

An unique solution to shorten the Gas Turbine Major Overhaul duration was designed and implemented in

Three (3) Gas Turbines

|

| |

|

| GT COMBUSTION CHAMBER_BEFORE |

| |

|

|

|

| GT COMBUSTION CHAMBER_AFTER |

|

| |

|

ANALYSIS , TROUBLE SHOOTING, PERFORMANCE TESTING OF ECP AT SEM CALACA POWER STATION,

BATANGAS,PHILIPINES.

After installation by OEM, 100% performance could not be achieved. Analysis and trouble shooting

revealed the reason and it was successfully resolved.

|

| |

|

|

| ELECTROCHLORINATION PLANT OF CAPACITY 2 X 72KG PER HOUR

|

| |

|

|

|

| PERFORMANCE TESTING FOR 2000PPM AVAILABLE CHLORINE

|

|

| |

|

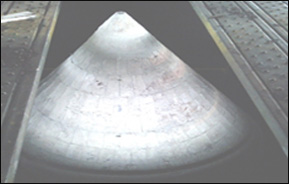

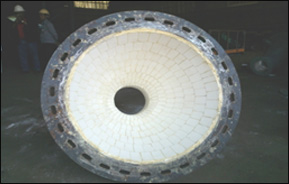

DESIGN,ENGINEERING,SUPPLY,INSTALLATION OF ALUMINA CERAMIC LINING FOR IRON ORE SEPARATORS IN PERWAJA

STEEL.

Discharge Chute, Distributor Cone and Outlet Cone lined with Cheaper 92% Alumina Ceramic Tiles with 8.5

years wear life in place of expensive HARDOX Liner from Sweden wearing out in just 2.1 years.

|

| |

|

|

|

| CERAMIC LINED CHUTES |

CERAMIC LINED SEPARATOR CONES |

|

| |

|

|

|

|

| CERAMIC LINED CONE |

|

|

| |

|

INSPECTION OF SACRIFICIAL ANODE CP SYSTEM IN JIMAH POWER (2 X 700MW COAL FIRED POWER PLANT)

Inspection of 251 nos. of Aluminium alloy anodes installed in Cooling water pipe line starting from sea

water intake until Condenser Outlet

|

| |

|

|

| INSPECTION OF AL ALLOY CP ANODES |

IDENTIFICATION OF DAMAGED ANODES |

| |

|

|

|

| CHECKING OF ANODE |

|

| |

|

REPAIR AND WELDING OF TANTALUM BAYONET HEAT EXCHANGERS IN PLATINUM ENERGY SDN BHD (A BIO DIESEL PLANT),

SEREMBAN.

Tantalum Bayonet Heat Exchangers used in Glass Lined Reactors for Bio Diesel Plant is a very expensive

equipment. The heat exchangers are made out of 0.5mm thick Tantalum tubes. Finding a crack and welding

the cracked Tantalum tube is a highly specialised and skilled job.

|

| |

|

|

|

|

VIEW OF Ta BAYONET HEAT EXCHANGER

INSIDE

GLASS LINED REACTOR

|

PULLED OUT Ta BAYONET HEAT EXCHANGER

FROM INSIDE GLASS LINED REACTOR

|

| |

|

|

|

|

IDENTIFIED LEAKING POINT

|

|

| |

|

Over view of the project carried out in Tanjung Bin Power Plant

VJIKKS ENGG POWER won a tender from MalaysiaLargest IPP MalakoffTanjung Bin Power Plant ( 4 x 1000MW),

a large Coal Fired Power Plant. In comparison with many tenders it won from Malakoff,

for providing solutions for their other Power Plants, this time, the tender won from its Tanjung Bin

Power Plant was totally for a different area of expertise. The job is to identify the thinning PF

(Pulverised Fuel) pipe line elbows installed along the PF lines starting from Mill to the burner in a

1000MW Power Plant, to remove and replace with new elbows.

Successfully 65 nos of thinning PF Line Elbows were identified and replaced during the plant outage

work in December 2015.Despite completing the job, in Tanjung Bin Power Plant , VJIKKS ENGG POWER (M) SDN

BHD, based on the sound and wide experience of their pool of Technical personnel, advised a better and

prudent solution, to instead of just replacing the thinning elbows with new expensive fabricated elbows.

|

| |

|

|

| |

|

Overview of the project carried out in Kapar Energy Venture

Kapar Energy Venture is the second largest Coal Fired Power Plant in Malaysia. VJIKKS ENGG POWER won

and successfully executed a project to remove old/corroded PF straight pipes in one of their 500W unit,

without any wear resistant lining and to manufacture, supply and install with newly fabricated spools

lined with wear resistant Alumina Ceramic material.

|

| |

|

|

| |

|

With the strong team of Indian and Malaysian Engineering professionals who are experienced in

Erection,Commissioning,Operation and Maintenance of Power, Chemical and Refinery Plants, the company has

already entered vigorously into Design, Engineering, Manufacturing, Installation, Commissioning and also

Training and Handing over.

Having made successful entry into Design, Engineering, Manufacturing, Installation, Commissioning and

also Training and Handing over. The team has started entering into maintenance of specialised system and

equipment like Electrochlorinators ( Electrolysers) in Power Plants.

Recently, OEM Sanilec designed Electrolyser of capacity 163.3Kg/day with Seven Cells and each cell with

Three packs installed in Phalawan Power, Malaysia was successfully serviced.

All the defects were professionally identified, reported to customer and recommended innovative routine

maintenance methods.

|

| |

|

|

|

|

Installation after servicing in progress

|

Installation after servicing in progress

|

| |

|

|

|

|

|

Front and Rear of ECP after servicing& installation

|

| |

|

|

|

|

Inspection after servicing& installation

|

|

| |

|

LAFARGE,KANTHAN

Every 3 monthly replaced Mill out let baffle plate were replaced with Alumina Ceramic lined Baffle

plates, so far 6 months in service without any replacement ; photos below are after 6 months

|

| |

|

|

|

|

Fig 1 & 2 :Raw mill LV separator Static Guide vane wear plate

installed with Ceramic Lining

|

| |

|

|

|

|

Fig 3 : Full view Raw mill LV separator Static Guide vane wear plate

installed with Ceramic Lining

|

|

| |

|

INSTALLATION CARRIED OUT IN OTHER COUNTRIES

|

| |

|

|

|

Fig 1: Several PF Lines installed in DOOSANKorean Power Plant

|

| |

|

|

|

|

Fig 2: Installation @ Al khalij cement Qatar

|

| |

|

|

|

| |

|

|

|

Fig 3: Installation of Mill Grit Cone Ceramic Lining at

Thailand

|

|

| |

|

EVERTS, MALAYSIA ( Baloon Manufacturer)

|

| Ceramic lining to replace some brick lining; Mill used

for grinding Titanium Dioxide) |

| |

|

|

|

|

Fig 1: Mill where Ceramic Lining Installed

|

Fig 2: New Tiles

|

| |

|

|

|

|

|

Fig 3: Removed old Tiles

|

Fig 4: Surface Preparation

|

| |

|

|

|

|

|

Fig 5: Tiles installation in progress

|

| |

|

|

|

Fig 6: Completed Ceramic Lining in the mill

|

|

PIGGY - BACK CONNECTIONS IN LARGE NUMBERS AND SPECIALISED HELIUM LEAK TEST

ON PIGGY BACK CONNECTIONS for PETRONAS RAPID PROJECT

|

|

Malaysian oil and gas company Petroliam Nasional Berhad (Petronas) is developing a

refinery and petrochemical integrated development project (RAPID) and other associated facilities

in Pengerang, Southern Johor, Malaysia, through a project called Pengerang Integrated Complex

(PIC).

Launched in May 2012, PIC is part of the larger Pengerang Integrated Petroleum Complex (PIPC)

proposed by the Johor state government. Total investment for the PIPC project is approximately

MYR97bn ($27bn), of which the RAPID project costs MYR57bn ($16bn) and the associated facilities

require MYR40bn ($11bn).

Almost every company in Malaysia have been looking for a share in this massive project.

VJIKKS ENGG POWER (M) SDN BHD also got an opportunity to serve a role in that

project.

Yes. It received Purchase Order to supply 20000meter length of KYNAR/HMWPE cable and 20000meter

length of MMO Coated Titanium Wire anode, to make more than 1400 piggy back connections and

finally to test the connections by specialized Helium Leak test method.

The entire scope of work is meant for ICCP ( Impressed Current Cathodic Protection) system of the

large storage tanks. The project was successfully delivered and also successfully executed under

the stringent specifications of Petronas.

|

|

|

INSTALLATION and TESTING OF DC BUS BAR FOR ELECTROLYSER

Installation of 400mm (W) x 80mm (T) x 66meter Aluminium DC bus bar system for Electrolyser to carry

high DC current.

|

| |

|

|

|

|

Preparation for welding

|

Completed welding joints at Electrolyser end

|

| |

|

|

|

|

|

One of the 52 welded joints

|

NDT in progress

|

| |

|

|

|

|

|

Termination in progress at Transformer/Rectifier end

|

completed installation at Transformer/Rectifier end

|

| |

|

|

|

|

|

Installation of DCDS

|

Cable Termination in Progress

|

| |

|

|

|

|

Elect Test in progress

|

|

|

ICCP (Impressed Current Cathodic Protection) Using Sled anode for JIMAH Power Plant

(2 x700MW)

Sled anode is nothing but assembly of a set of Pure Iron anodes embedded in a concrete slab. The

dimension and weight of the sled anode varies depending upon the CP current requirement.

Sled anodes are used generally for cathodic protection of sheet piles of the sea water intake

structure in Power Plants.

In JIMAH Power Plant (2 x 700MW), ICCP using Sled Anode for their sea water intake sheet pile

protection was found inoperative due to defective sled anode. After successful winning of tender,

new sled anodes were designed manufactured, installed and ICCP was reestablished.

|

| Few Photos of Installation |

|

|

|

ENGINEERING, SUPPLY, INSTALLATION,TESTING AND COMMISSIONING OF Fire Detection

System using Fire Trace in MalaysiaKuala Langkat Power Plant which involves all the MCCs

and Control Panels in a 720MW Combined Cycle Power Plant.

|

| |

|

|

| |

| |

|

DESIGN, ENGINEERING, SUPPLY, INSTALLATION,TESTING , COMMISSIONING, TRAINING ,

MAINTENANCE and HANDING OVER OF Impressed Current Cathodic Protection (ICCP)

System for Sea Water Intake Structures in 3x700MW TNB Manjung Coal Fired Power Plant.

|

| |

|

|

| |

|

|

|

|

DESIGN, ENGINEERING, MANUFACTURING, SUPPLY, INSTALLATION, TESTING ,

COMMISSIONING OF 2X17.5KG/HR Electrolyser in Hyflux Tuas Spring Desalination Plant,

Singapore.

|

| |

|

|

|

INSPECTION AND REPLACEMENT OF SACRIFICIAL ANODES in Sea Water Intake Structure SACP ( Sacrificial Anode

Cathodic Protection System) in U-30 ( 1000MW) Tanjung Bin Power Plant.

|

| |

|

|

| |

|

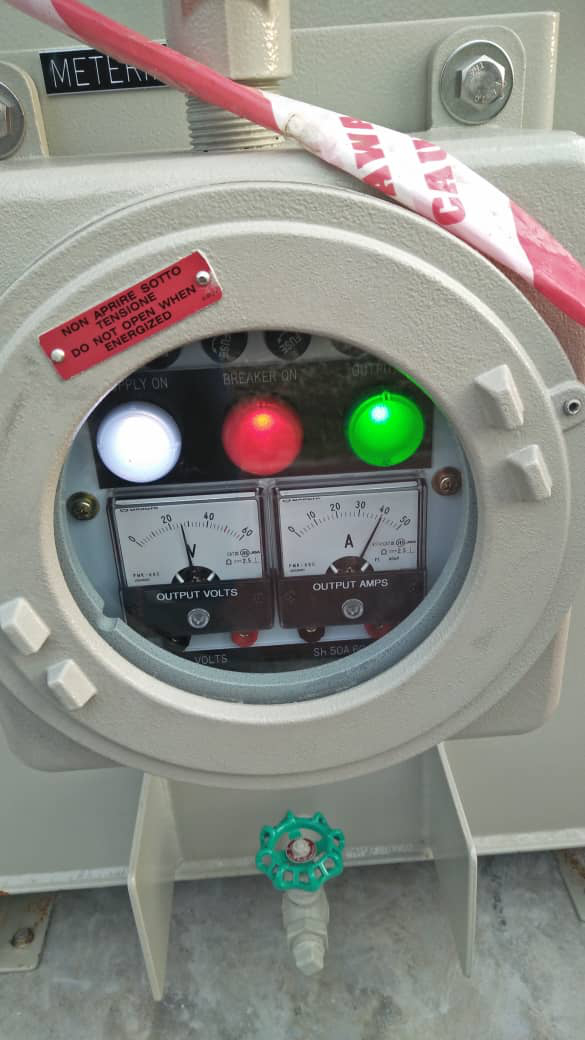

INSTALLATION,TESTING AND COMMISSIONING OF Impressed Current Cathodic Protection System (ICCP) in

MalaysiaIDEMITSU Chemical Plant for its huge chemical storage tankprotection which involves Micropiling to

install anodes at 40m depth and Transformer Rectifier (TRU) panel installation.

|

Anodes to be installed

Anodes to be installed

|

Micropiling for Anode Installation

Micropiling for Anode Installation

|

| |

|

One of the Anodes installed at 40m depth

One of the Anodes installed at 40m depth

|

| |

|

Explosion Proof TRU panel

Explosion Proof TRU panel

|

Power DB instn. Completed

Power DB instn. Completed

|

| |

|

TRU charged

TRU charged

|

|